ItemAware – The Inventory Management System That Outperforms Competition

ItemAware is the cutting-edge tool tracking and inventory management system with GPS functionality that saves you both time and money. Read more below to learn why our system continually outperforms our competitors.

Healthy Competition

Competition is a natural part of business. Without it, companies wouldn’t be motivated to be innovative, client-focused, and forward thinking. Healthy competition is to the benefit of consumers because it pushes businesses to revolutionize industries as they look for ways to stand out among the crowd.

At Aware Innovations, we are not naïve to our competitors’ offerings. We can appreciate their efforts as we continually seek to pioneer the inventory management system and tool tracking industries. Our team of experts continually evaluate the capabilities of our competitors’ products to ensure that our robust software remains at the forefront.

Continue reading to discover how ItemAware reduces manpower requirements, prioritizes innovation, stores data, and offers other advanced capabilities.

ItemAware Capabilities

Level of Effort

Time is an invaluable, and often costly, resource that most companies cannot afford to waste. Knowing this, why would you invest in a system that involves manual labor when you can lighten your workload by using our time-saving software? You would be taking on more physical work if you choose to use our competitor’s product over ours.

Our competitor’s above referenced tool tracking and inventory management system uses BLE or barcode scanning – meaning that an asset is only tracked if a barcode is manually scanned or a device with their proprietary BLE application is nearby. The manual effort of barcode scanning or the crowdsourcing needed for BLE implies that you will be paying your employees to operate a barcode or BLE app while scanning or being near each box and asset individually. This does not help you understand where all your items were last located.

Human error happens. If you are relying on manual scanning, it is not only possible, but likely, that there will be mistakes hidden within your inventory management system. Meanwhile, you will only become aware of lost or misplaced tools at the time the user does their inventory. Could you imagine the headache of attempting to track down misplaced equipment at the end of an employee’s shift? This would only be further exasperated if your common practice is for workers to visit multiple jobsites throughout their workday.

ItemAware’s tool tracking software has GPS functionality and has revolutionized the way companies keep track of their inventory. Our innovative technology is always scanning to make certain that you know exactly where your tools are – whenever, wherever you need them. Furthermore, our tool tracking software is automatic, eliminating the need for expensive and time-consuming physical work.

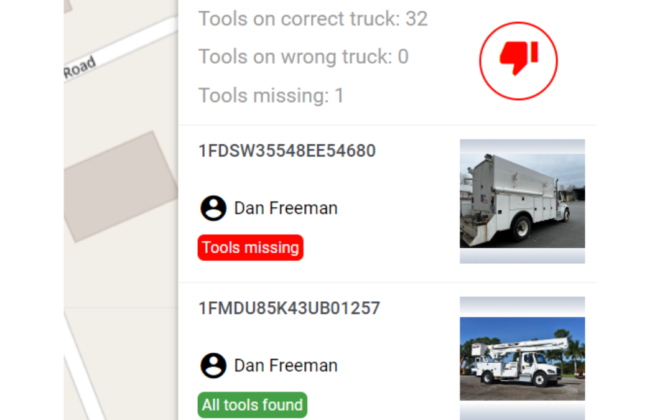

Our inventive software will take the worry out of tool tracking. ItemAware automatically detects loss or movement of all tagged equipment in real-time with geo-location in the field. You will have instant access to view the location of all your tools. If an item is missing, ItemAware will show GPS coordinates of its last-seen location. This unique capability will save you both time and money previously spent on searching for lost tools.

Cutting Edge Technology

As mentioned above, our competitor’s software relies on either barcode or Bluetooth Low Energy (BLE) scanning. Again, this requires manual scanning or a BLE device with proprietary software to keep track of inventory. In contrast, ItemAware is technology agnostic – it can work with whatever tech is best for your requirements. This means we can help you determine which technology is right for your use case: Internet of Things (IoT), RFID, GPS, Barcodes, Ultra-Wideband (UWB), Bluetooth (BLE), or Wi-Fi.

To learn more about the technology behind a Real-Time Locating System (RTLS), read this article.

A particular area of innovation is ItemAware’s use of Radio Frequency Identification (RFID) tags.

The benefits of RFID’s ability to track item location and data include:

- Increased supply chain efficiency

- Reduced human errors in inventory

- Eliminated cost of replacing lost or stolen items

- Elevated security

As you can imagine, the benefits of RFID technology are significant – and this isn’t even an exhaustive list. At Aware Innovations, we pride ourselves on being at the forefront of innovation. We are a team of experts who designs, implements and sustains asset management and tracking solutions for enterprises of all sizes. Our team won’t stop until all your inventory management and tool tracking needs are met with ease.

Data Management

Our inventory management system goes beyond our competitor’s use of cloud-based technology to store data. ItemAware offers the flexibility to house data using a cloud-based system or it can be connected to a client’s server. Our team will work alongside you to determine which data storage method best suits your unique needs.

Have you ever needed to enter data but had no access to the internet? ItemAware eliminates the need to wait for internet access to get your job done. Our modern software can cache information even when the user is offline. This gives you the freedom to enter data whenever, wherever you are.

Alerts and Reporting

Alerts are an important part of any tool tracking and inventory management system. They serve as an extra layer of oversight – reminding you of important deadlines while simultaneously making you aware of inventory issues.

Our competitors’ software limits alerts to service reminders as well as tool tracking updates. Their platforms can notify you when your equipment has moved; however, they do not offer any further capabilities beyond this.

In comparison, ItemAware has the intelligence to take on both forementioned tasks while also reminding you of compliance and inspection deadlines. Furthermore, our robust software doesn’t just stop at alerting you when a tool has been moved. It goes a few steps further by notifying you if an item is missing or has been placed in the wrong location.

Our intuitive software also offers customizable reports as well as compliance reporting – two items that are not offered by our competitors. ItemAware allows you to prioritize worker safety and remain OSHA compliant with calibration, maintenance, and inspection due dates tracked conveniently within our software.

Failure to remain OSHA compliant can result in significant financial penalties as well as unwanted legal issues for your company. Prevent these fines while simultaneously prioritizing worker safety by allowing ItemAware to keep detailed inspection records for you.

How much time and energy would you save if you didn’t have to manually keep track of your compliance deadlines?

ItemAware – The Intelligent Software Revolutionizing the Tool Tracking and Inventory Management System Industries

At Aware Innovations, we pride ourselves on offering a premium, user-friendly product that continually outperforms our competition. Our robust software can be easily tailored to meet your unique needs while taking the headache out of tool tracking and inventory management.

We are here to help you. Get started today by requesting a free 30-minute demo with one of our knowledgeable representatives.

About the Author

Jessica Frye is an expert content writer with 7+ years of professional writing experience. She earned her B.A. in Communication Studies from Wright State University and has worked alongside companies in both the for-profit and non-profit sectors. Jessica is passionate about community and enjoys using the power of words to not only cause people to react but to take initiative.

Tags In

Categories

- Awards (1)

- Cellular GPS (1)

- Compliance (3)

- Events (4)

- Features (2)

- Inventory Management (4)

- Item Management (4)

- ItemAware (14)

- News (3)

- Quality (1)

- RFID (8)

- RTLS (5)

- Software (8)

- Traceability (4)

- Uncategorized (2)